When it comes to substantial lifting operations, confidence is placed on equipment that can handle the job with unwavering strength and safety. Wire rope lifting slings have demonstrated themselves as a reliable choice for countless applications, offering exceptional load-bearing capacity while prioritizing operator wellbeing.

Constructed from high-quality steel wire, these slings are designed to withstand even the most challenging lifting situations. The flexible nature of wire rope allows for easy manipulation and positioning around diverse loads, ensuring a secure and stable grip.

- Furthermore, the longevity of wire rope slings makes them a cost-effective solution in the long run, as they can withstand repeated use without compromising their strength.

- It is crucial to always inspect your wire rope slings consistently for any signs of wear and tear. This includes observing for frayed wires, kinks, or damage to the protective coating.

- In conclusion, choosing wire rope lifting slings for your operation means investing in a combination of power and safety that can elevate your performance and provide peace of mind.

Specialized Cable Assemblies for Targeted Applications

In sectors requiring high performance and reliability, standard cable assemblies often fall short. This is where custom cable assemblies come into play, providing customized solutions that meet the unique demands of your application. By utilizing advanced materials and precise construction techniques, custom cable assemblies ensure optimal signal transmission, robust performance, and enhanced safety.

Whether you require custom made wire rope cables cables for medical applications, data transfer, or other specialized field, custom cable assemblies offer the flexibility to meet your exact specifications.

- Selecting a reputable manufacturer with experience in crafting custom cable assemblies is vital to ensure the highest quality of performance and reliability.

Heavy-Duty Cables : Powering Critical Lifts

In the realm of heavy industry and demanding applications, a winch rope's strength and durability are paramount. Lifting cables , built to withstand extreme stress and abrasion, serve as vital components for countless operations. Whether it's hoisting hefty loads , recovering disabled transport, or maneuvering dense payloads, these robust ropes provide the steadfast force necessary to overcome obstacles .

Constructed from advanced composites, durable winch ropes exhibit exceptional tensile strength . They resist deterioration and fraying even under the most harsh conditions .

- Choosing the right winch rope is crucial to ensure optimal performance of your tasks.

- Consider factors such as working load limit, rope diameter, and material composition when making your choice.

Choosing the Right Wire Rope Fittings: A Guide to Secure Connections

When it comes to wire rope applications, selecting the right fittings is paramount for ensuring safety and reliability. Wire rope fittings serve as critical connection points between wire ropes and other elements, transmitting loads and stopping slippage or separation. Choosing the appropriate fitting depends on a variety of factors, including the wire rope's diameter, material, working load limit, and the specific application.

- Evaluate the type of load being carried.

- Determine the environmental conditions, such as temperature extremes or corrosive agents

- Examine industry standards and safety guidelines for specific applications.

Wire Rope Maintenance: Extending Lifespan and Ensuring Performance

Maintaining your wire rope properly is essential for ensuring it performs at its best and lasts as long as possible. Overlooking routine maintenance can lead to premature wear and tear, jeopardizing safety and efficiency.

Here are some key steps to incorporate into your wire rope maintenance schedule:

* Continuously inspect the wire rope for visible wear. Look for things like corrosion, kinks, fraying, or broken wires.

* Keep the wire rope clean and free of contaminants. Use a soft brush and appropriate cleaning solution to remove any buildup.

* Lubricate the wire rope as advised by the manufacturer.

* Store wire ropes properly in a dry, cool, and sheltered environment when not in use.

By following these simple maintenance practices, you can prolong the lifespan of your wire rope and ensure it continues to operate safely and effectively.

Understanding Wire Rope Construction: Key Factors for Optimal Use

Wire rope construction plays a crucial/vital/essential role in determining its strength, durability, and overall performance. A thorough understanding of the various components and construction methods is imperative/necessary/critical for selecting the right wire rope for specific applications.

One key factor to consider is the type of wire strand/filament used in the construction. Wire ropes can be constructed/made/formed from a variety of materials, including steel, stainless steel, and nylon. The choice of material depends on factors such as load capacity, environmental conditions, and corrosive resistance.

Another important aspect is the number of strands and wires per strand. Generally/Typically/Often, wire ropes are comprised of/made up of/consist of multiple strands twisted together to form a larger rope. The number of strands and wires per strand affects the rope's flexibility, tensile strength, and abrasion resistance.

Finally, the construction method also plays a role in the wire rope's performance. Common construction methods include conventional/standard/traditional, hawser laid, and filler laid. Each method has its own advantages and disadvantages, and the choice of method depends on the intended application.

Understanding these key factors can help ensure that you select the best possible wire rope for your specific needs and achieve the desired results.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Jenna Jameson Then & Now!

Jenna Jameson Then & Now! Seth Green Then & Now!

Seth Green Then & Now! Kelly Le Brock Then & Now!

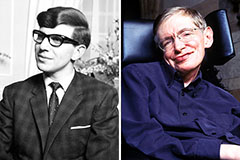

Kelly Le Brock Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!